Products and Services

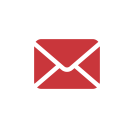

Photomask Blanks inspection system

「LODAS™ – AI50/100」

Features:

- For Photomask Blanks for Semiconductor Shipment Inspection, Process Evaluation

- Defect analysis by differential interference microscope

- Inspection target : Photomask Substrate, Cr, Resist, MoSi

- Inspection items : Particles, internal defects (Option)

- Inspection sensitivity: PDM defect size 0.1 μm (AI100)

「LODAS™ – BI8」

Features:

- Chromium, halftone, and resist films can be inspected.

- Automatic identification of white and black defects.

- Simultaneous inspection of not only surface defects, but also internal and backside defects.

- Four types of review images for defect analysis.

- “AI Classify” for defect classification and good/failure judgment.

- Maintenance free.

- World Primer! Hybrid inspection system using reflected scattered light, transmitted scattered light, and confocal light

- Inspecting for defects that have not been inspected before.

Target defect : Particles, Scratches, Pits, Voids

Specifications:

- Inspection Laser: 405nm 200mW Laser Diode

- Inspection Time:180sec

- Inspection Target:6inch Photomask blanks

- Equipment Size:W×D×H=450×500×730mm

- Utility: AC100V~200V 10A

Glass wafer inspection system

「LODAS™ – BI12」

Features:

- For Glass wafer shipping inspection, process evaluation

- Simultaneous inspection of front, back and internal defects

- Determination and analysis of front and back surface defects using differential interference microscope

- Inspection target:12 inches, 8 inches, 6 inches, Glass wafer

- Inspection items :Particles on front and back surfaces, internal defects

Compound semiconductor SiC,GaN inspection equipment

「LODAS™ – CI8」

Features:

- Capable of inspecting both SiC single crystal wafers and epitaxial wafers.

- Simultaneous inspection of surface defects, internal defects, and backside defects.

- Four types of review images for defect analysis.

- “AI Classify” classifies defects and determines whether they are good or failure.

- Maintenance free.

- World Primer! Hybrid inspection system using reflected scattered light, transmitted scattered light, and confocal light.

- Inspecting for defects that have not been inspected before.

Target defect : Particles, Scratches, Crystal defects

Specifications:

- Inspection Laser: 405nm 200mW

- Inspection Time:200sec(size:4inch)

- Inspection Target:2 inches, 3 inches, 4 inches, 6 inches wafer

- Equipment Size:W×D×H=450×500×730mm

- Utility: AC100V~200V 10A

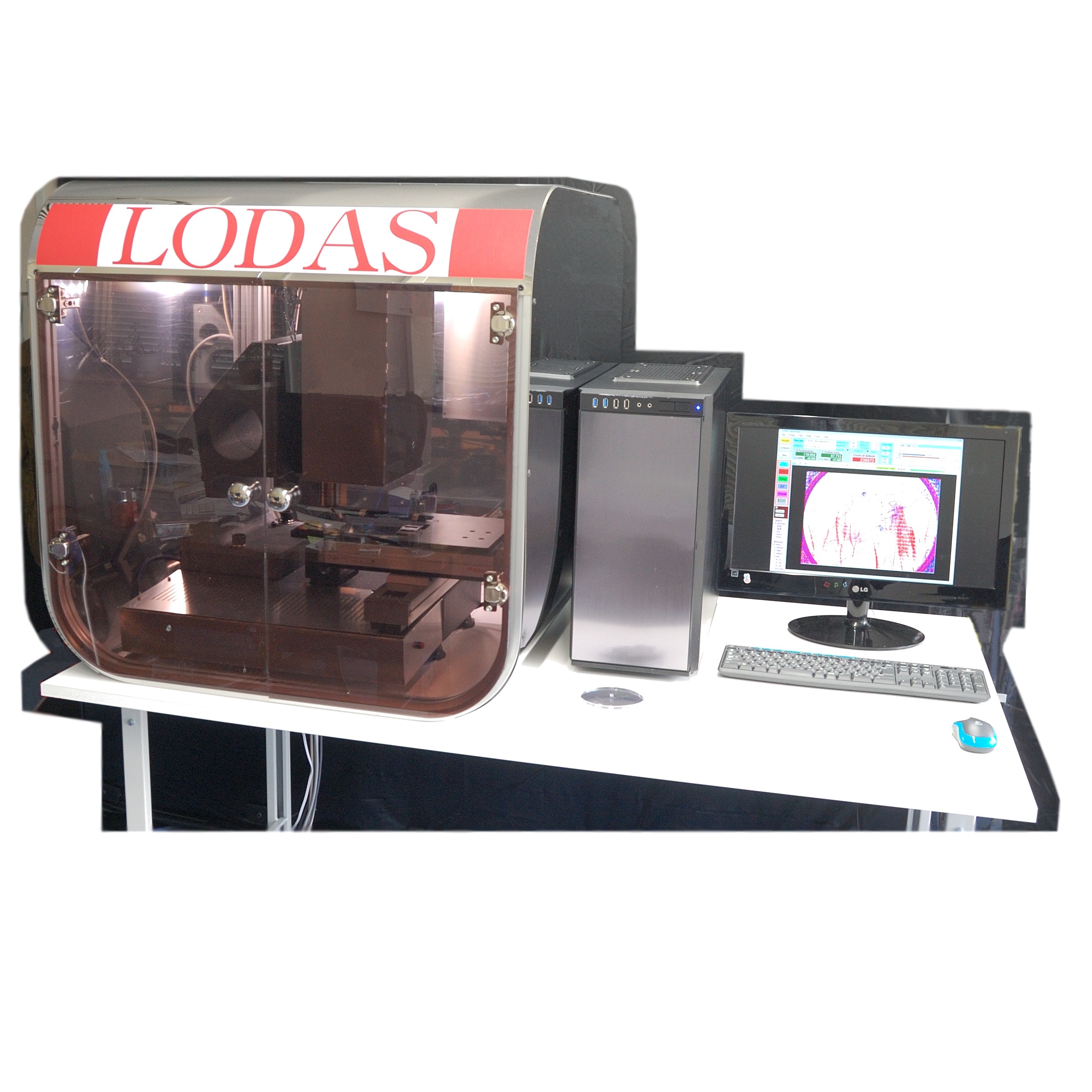

FPD Photomask inspection system

「LODAS™ – LI series」

Features:

- Simultaneous A-side and B-side inspection.

- G10, G8, G6 sizes available

- Determination and analysis of front and back surface defects using differential interference microscope

- Inspection target :FPD Photomask Substrate、Cr、Resist Blanks

- Inspection items :Front and back surface particles, internal defects

Built-in Optical inspection system

「LODAS™ – BOIS」

Features:

- It can be used to inspect the results of various process scenes in accordance with the customer’s cleaning, polishing, and deposition equipment.

- Reduces processing time and costs by eliminating extra processing steps.

- Quality can be improved without installing inspection equipment, saving space and cost.

- The interface supports RS232C, IO, Ethernet, etc., and can be easily connected to peripheral devices.

Target defect : Particles, Scratches, Pits, etc.

Specifications:

- Inspection Laser: 405nm 200mW Laser Diode

- Inspection Sensitivity:100 nm PSL

- Inspection Target:Si wafer, compound semiconductor wafer, glass substrate, etc.

- Equipment Size:W×D×H=250×200×500mm

Maintenance Service

Maintenance and repair of our inspection equipment

- Periodic support for maintaining performance immediately after equipment setup is complete.

- On-call service support. Open every day of the year. Phone number : 03-6451-4379

- We will respond to new requests sincerely.

- We will hold technical seminars and improve manuals so that customers can perform maintenance and parts replacement themselves.

- We will support you with free diagnosis service for consumables such as HDD and laser light source.